Enhance efficiency with expert mechanical system optimisation support.

Enhance efficiency with expert mechanical system optimisation support.

Blog Article

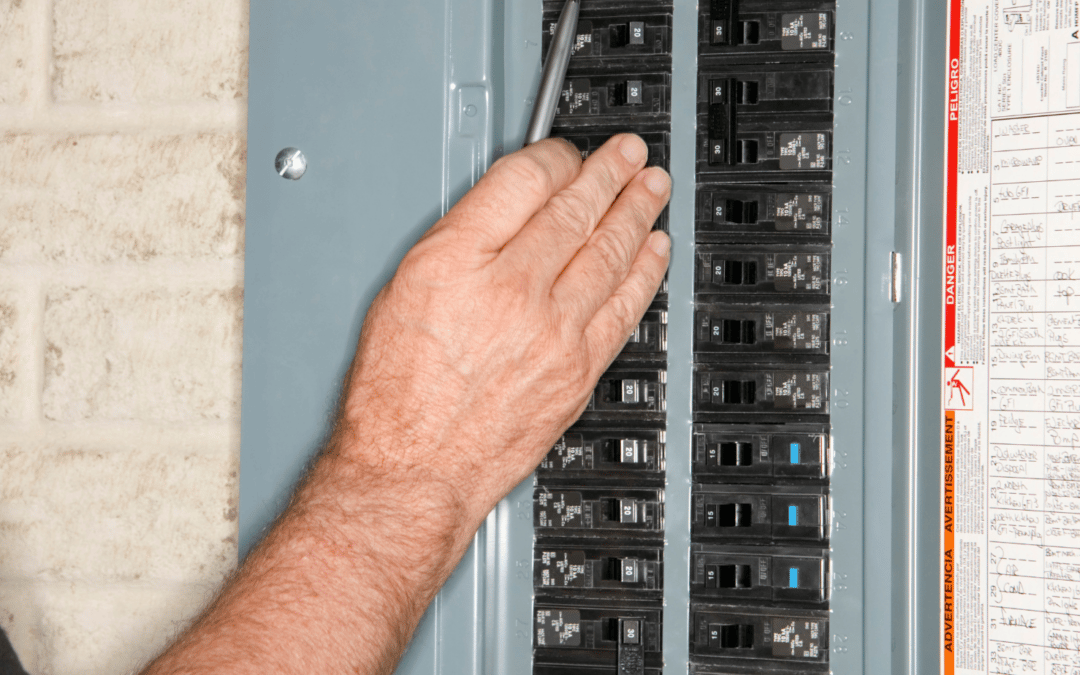

Top Tips for Effective Electric System Troubleshooting

Fixing electric systems calls for a methodical strategy, grounded in an extensive understanding of electrical principles and safety and security methods. By acquainting oneself with circuit components, using vital tools, and sticking to an organized analysis method, specialists can efficiently recognize and deal with concerns. The subtleties of reliable troubleshooting prolong past mere technical understanding; recognizing how to document searchings for and focus on safety can substantially influence results. As we discover these vital components further, it becomes clear that mastering this procedure is not simply advantageous but necessary for success in the area.

Understand the Fundamentals

Recognizing the fundamentals of electrical systems is necessary for efficient troubleshooting, as a strong structure permits specialists to identify and fix problems much more efficiently. A thorough understanding of electric principles, such as voltage, present, resistance, and power, is crucial in identifying the source of troubles. Voltage is the electrical prospective difference that drives present through a circuit, while resistance opposes the circulation of existing, influencing the general performance of the system.

Experience with circuit parts, consisting of resistors, capacitors, diodes, and changes, is also extremely important. Each element plays a distinctive function in circuit actions and can impact performance when malfunctioning. Additionally, recognizing series and identical circuit configurations is crucial, as these arrangements affect the circulation of voltage and present within the system.

Technicians should be conscious of prospective dangers, such as shock and brief circuits, to implement safe troubleshooting practices. By grasping these foundational concepts, professionals boost their ability to perform effective diagnostics and fixings, inevitably leading to boosted efficiency and integrity of electric systems (electrical system troubleshooting).

Gather Necessary Devices

Effective troubleshooting of electrical systems calls for the ideal set of devices to identify and fix concerns properly. Necessary tools include a multimeter, which gauges voltage, present, and resistance, allowing for specific evaluations of electrical elements.

In addition, insulated hand devices such as screwdrivers, pliers, and cord strippers are important for securely controling electrical links. It is also advisable to have a circuit tester handy to validate the visibility of voltage in outlets and cords. For more complicated systems, a thermal imaging video camera can aid discover overheating parts, suggesting possible failures.

Follow a Systematic Method

Having gathered the suitable tools, the following action in fixing electric systems is to adhere to an organized method. A methodical technique makes sure that specialists can identify mistakes successfully and properly, decreasing downtime and stopping unneeded fixings.

Begin by evaluating the system's schematic diagrams and specifications. Understanding the layout and functional parameters will offer context for diagnosing issues. Next off, separate the issue area by utilizing a procedure of elimination. This involves monitoring each element systematically, starting from the source of power and functioning in the direction of the tons.

Make use of testing devices, such as multimeters and oscilloscopes, to collect unbiased data concerning voltage, that site present, and resistance at various factors within the system. This empirical evidence will certainly assist your troubleshooting efforts and aid to verify or eliminate possible causes of failing.

Furthermore, think about environmental aspects Get More Information that may affect the system's performance, such as temperature level fluctuations or moisture access. A detailed inspection of circuitry, connections, and parts will make certain that all possibilities are accounted for.

Paper Your Searchings For

Detailed documentation is necessary in the troubleshooting process of electrical systems. This method not just help in recognizing the root cause of the problem however additionally offers as a referral for future troubleshooting efforts.

In addition, keeping a log of parts changed or repairs performed is indispensable. This information sustains supply administration and can help analyze the long life and dependability of specific parts.

Eventually, the documentation procedure must be comprehensive yet succinct, allowing easy access and evaluation - electrical system troubleshooting. By focusing on in-depth documentation, specialists can develop a beneficial understanding base that not only help in current troubleshooting yet also encourages future maintenance efforts, thus improving overall system reliability

Prioritize Precaution

Identifying the fundamental threats related to see this here electric systems is essential for making certain safety and security during troubleshooting. Electric shock, burns, and equipment damage are simply a few of the potential dangers that technicians deal with. Focusing on security measures is not just a lawful responsibility but additionally an ethical critical that safeguards both the professional and the surrounding environment.

Before starting any kind of troubleshooting task, service technicians should don suitable individual safety tools (PPE), including shielded gloves, shatterproof glass, and flame-resistant apparel. Ensuring that the workplace is completely dry and cost-free of mess can considerably lower the threat of mishaps. Furthermore, it is necessary to de-energize circuits prior to starting any kind of job, validating that they are not endure the use of a multimeter or voltage tester.

Developing clear interaction protocols with staff member is additionally essential; this makes certain that every person recognizes possible hazards and the condition of the electric system being functioned on. Lastly, having an emergency action strategy in place can confirm invaluable in case of a case. By prioritizing precaution, technicians can effectively minimize dangers and foster a safer office.

Final Thought

Efficient electric system fixing depends on a comprehensive understanding of basic concepts and a methodical strategy. By collecting important devices, adhering to systematic examination techniques, and diligently recording findings, the repairing process becomes a lot more efficient and dependable. Focusing on safety actions makes sure the well-being of individuals entailed and the stability of the electric system. Implementing these approaches will improve the troubleshooting experience, bring about quicker resolutions and enhanced functional efficiency in electrical systems.

Report this page